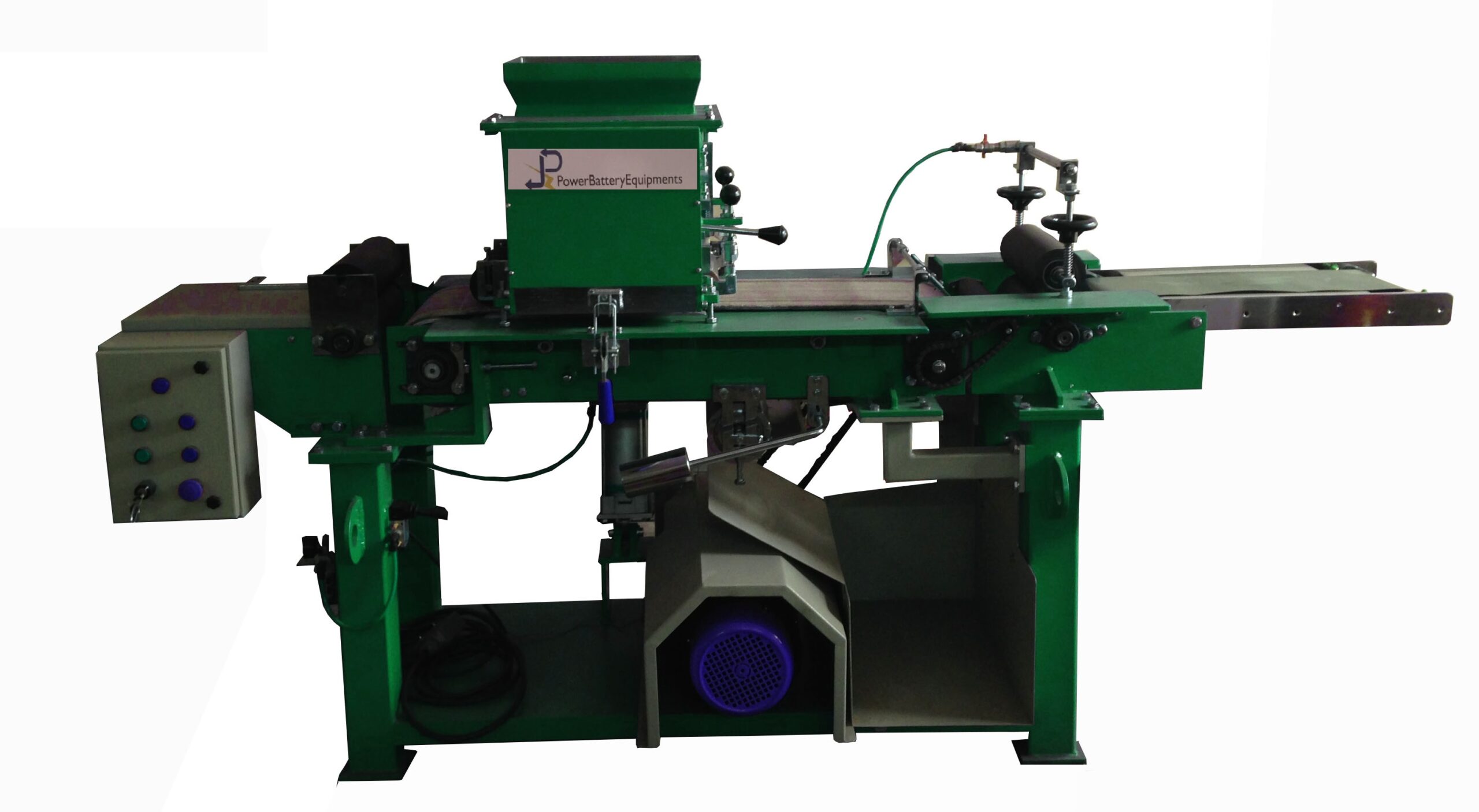

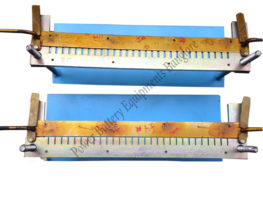

• Suitable for casting 3 to 4 tubular (IT) grids double cavity per min & 6 to 7 automotive grids (ns40,automotive, din & industrial negative) .

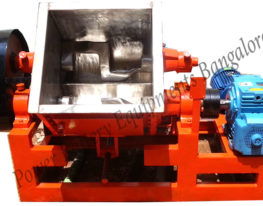

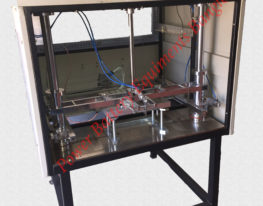

It’s best suitable for selenium & antimony alloys. The machine consist of one (1) main machine, grid mold, 700 to 800 kg lead

melting furnace with lead pump, Feedline(also available in top mounted) and a main control panel.

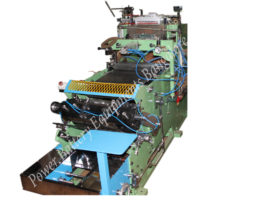

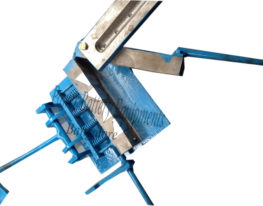

• The machine is made up of rigid MS structural frame on which the grid mold is fitted. opening & closing of the mold is done by pneumatic cylinder actuated by a solenoid valve. Continuous opening closing of mold is sequenced by the help of a sequence controller , also cooling time is achieved in this process for the molds..

• Lead is poured in the molds with the help of ladle, & the ladle is fixed with a small pneumatic cylinder actuated by a solenoid valve. Lead

is poured automatically when mold is closed,& ladle automatically gets filled by a centrifugal lead pump fixed with the furnace with a

flow line (feed line)pipe having heaters so that lead is not cooled while traveling from furnace to the ladle.